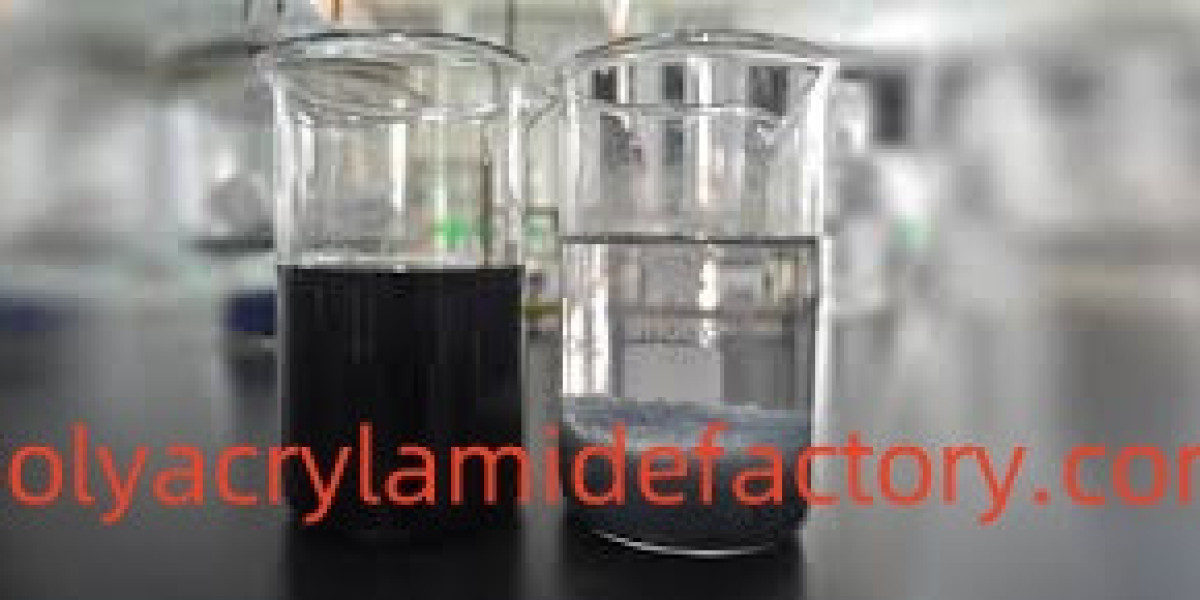

In the mining industry, managing the separation of solids from liquids is a critical process that ensures operational efficiency and environmental compliance. The use of chemical flocculants, especially anionic polyacrylamide emulsion , has become a cornerstone technology for improving the treatment of mine wastewater, slurry, and tailings. Understanding the flocculation mechanisms of this polymer emulsion helps mining engineers optimize process water clarity, sedimentation rates, and overall dewatering performance.

Flocculation is the aggregation of fine suspended particles into larger flocs that can settle or be filtered more easily. In mining slurries and wastewater, particles typically carry a negative surface charge, which causes them to repel one another, preventing natural settling. The unique properties of anionic polyacrylamide emulsions allow them to overcome this repulsive force primarily through two mechanisms: charge neutralization and polymer bridging.

Charge neutralization occurs when the polymer interacts with cations present in the slurry or process water. Although the polymer itself is anionic (negatively charged), it complexes with multivalent cations such as calcium or magnesium, which can neutralize the charges on particle surfaces. This reduces electrostatic repulsion and allows particles to come into closer contact.

Polymer bridging refers to the long-chain structure of the polyacrylamide molecule, which can adsorb onto multiple particles simultaneously. This physically links particles together into larger, more settleable aggregates called flocs. These flocs are porous and robust, allowing water to drain efficiently during sedimentation or filtration.

Anionic PAM emulsions are also designed to maintain their flocculation capabilities under the shear and turbulence conditions typical in mining operations. The emulsion form protects the polymer chains during storage and handling, enabling controlled release upon dilution and mixing in process streams.

The application of anionic polyacrylamide emulsions spans several critical areas within mining, including slurry thickening, tailings dewatering, clarifier performance, filter press operation, and water recycling. Each application benefits from the same fundamental flocculation mechanisms but operates under different process parameters.

| Application Area | Flocculation Role of Anionic PAM Emulsion |

|---|---|

| Slurry Thickening | Aggregates fine particles to enhance settling rate and clarity |

| Tailings Pond Management | Accelerates sedimentation to reduce pond volume and improve water |

| Clarifier Overflow | Reduces turbidity and improves solids capture |

| Filter Press Operation | Enhances cake formation, reducing moisture content |

| Water Recycling Systems | Improves solid-liquid separation, enabling cleaner water reuse |

In tailings management, the ability of anionic PAM emulsions to form large and dense flocs reduces settling time and pond size, which lowers environmental risks and saves space. In slurry thickening, these emulsions increase the efficiency of sedimentation tanks by promoting rapid particle aggregation, which in turn improves overflow water clarity and reduces the load on downstream equipment. During filtration, the polymer helps form firm cakes that are easier to dewater, shortening press cycle times and enhancing overall throughput.

The benefits of anionic polyacrylamide emulsions extend beyond process efficiency. These polymers help mining operations comply with stringent environmental regulations by significantly reducing total suspended solids (TSS) and chemical oxygen demand (COD) in discharge water. The ability to recycle clarified water back into the plant reduces freshwater consumption and promotes sustainable mining practices.

To achieve optimal flocculation performance, it is important to consider proper dosing, mixing, and storage of the emulsion. Dilution with clean water and gentle agitation before dosing ensures uniform polymer distribution. Storage in cool, shaded environments preserves emulsion stability and prevents premature degradation. Additionally, the chemical compatibility of the polymer with other treatment additives should be evaluated to avoid negative interactions.

With increasing pressure to reduce environmental footprints and improve resource efficiency, anionic polyacrylamide emulsions have become indispensable in modern mining operations. Their ability to deliver consistent, effective flocculation even under challenging conditions makes them a preferred choice for engineers and operators.

Polyacrylamidefactory is proud to offer high-quality anionic polyacrylamide emulsions tailored to the diverse needs of the mining industry. Our formulations are designed to maximize flocculation efficiency, accelerate sedimentation, and enhance water clarity, helping mining companies meet their operational and environmental goals with confidence. We provide comprehensive technical support to ensure the best dosing practices and process integration.

Discover how our advanced emulsions can optimize your mining processes by visiting:

https://www.polyacrylamidefactory.com/news/industry-news/how-does-hengfeng-anionic-polyacrylamide-emulsion-work.html